- Joined

- Sep 16, 2016

- Messages

- 399

- Reaction score

- 215

Rig Build Part #2

Stage 1 of the build can be found here

Eviction to the Garage

After sitting pretty in the office of over a year, we had visitors from over the pond which required me to move the rig into the garage as a temporary measure. During the process and lots of hard lifting (these things get very heavy and cumbersome to move) I quickly came the conclusion that I didn't want to be moving the rig again anytime soon. At this point I decided to try and make a permanent home for it in the garage.

First port of call was to get something comfortable onto the hard floor so I opted for some Foam Garage Mats to cover the floor, these worked really well being easy to clean and also acting as a bit of an insulator from the concrete floor.

With the rig in the garage I now had no monitors or TV to use, I wanted to keep the desktop real estate of my two 24” 1920x1200 monitors from the office but didn’t really want to occupy that much space in the garage. So to keep the desktop real estate whist keeping the space usage down I opted for a single 4k 27” LG 27UD58 this was one of the cheaper IPS based panela. I went the IPS route as it would not really be used for gaming but more desktop based activities where IPS had better colour reproduction and viewing angles.

Exploring upgrade options.

As the rig was now in the garage the noise and vibration wouldn't carry into the rest of the house I now had a bit more flexibility on the types of upgrades I could look at in this constantly evolving project. My Fanatec CSW v2 had served me well for almost two years, with only the customary high pitch electronics whine that is common on the CSW v2 to fault it. Since being installed in the rig it has been subjected to five 24/12hr endurance races and easily over 10,000 laps during the last year and has been rock solid throughout.

I always wanted to RMA the CSW v2 for the electronics whine, but in the busy schedule of the endurance racing this year I just couldn't find the time to be without a wheel for more than a couple of days. I'd always said to myself that one day that I'd go to a direct drive system.

The jump to a DD wheel comes with many knock on expenses above and beyond the motor/controller systems themselves, alongside that you need to source a wheel, shifter and button electronics to go alongside it and these can also get almost as expensive as the base motor/controller themselves.

I know recently a lot of people have been converting their Fanatec wheels rims using conversion kits so that they can then mount these onto the DD kits and this was something I was had been looking at. My main concern here was this was a semi-permanent change to the wheel rim so once a wheel was converted it wouldn’t be easy to re-attach to the CSW v2 which I planned to keep for the children and having the portability between the two was high on my list of criteria for a replacement drive system.

Whilst I was investigating the options for mounting the Fanatec rims to a DD wheel, I came across a UK sim-racing site that does lots of modifications for Sim-racing gear. In a chance conversation about which quick release system they would recommend for attaching to a Fanatec wheel they offered to manufacture a custom made adapter for a DD wheel. This adapter would allow me to keep the Fanatec Wheel RIM’s in their original configuration and replicate the mounting mechanism of the CSW v2 onto a DD system including preserving the operation of the shifters and buttons.

And below is the custom adapter that got the ball rolling

At this point all the blockers that were holding me back had been resolved via the custom conversation adapter, this would allow the purchase of the DD system without the big expense of purchasing a new wheel for the DD kit.

Choosing a Direct Drive System

I had been looking at the DD market evolve over the last year there were a couple of turnkey products available. At the high end you have the Leo-Bodnar SimSteering series of wheels and at a cheaper price point the SimXperience Accuforce based series.

Additionally there is another option that is popular in a lot of the Sim-Racing forums and that is referred to as the OSW (Open Sim Wheel) eco system. This is basically an open source project where different motor controllers, associated electronics and motors can be combined in a DIY based project. Historically this has meant a lot of DIY to bring such a project into life and can be quite complex to the non-electronic engineer. In the last year this has become much simpler with the release of the SimuCube controller board. This board integrates a lot of the elements of the previous systems into one controller board designed specifically for simulation based environments such as Sim-Racing and all that is then required is to add a supported motor and a PSU.

With this change we also saw a lot of Sim-Racing companies starting to sell either a kit form of such systems or a fully assembled version. Whilst still a bit of a DIY project most of the complexity in these kits has been removed and this makes it accessible to a wider market.

Two of the more regarded EU companies that sell such kits are SimRacingBay and Sim-plicity, knowing that the kits are pretty much made from the same core components and both companies are generally held in good regard I opted for the UK based supplier as this came out about 20% cheaper for me.

I opted for the larger more powerful of the two systems on offer, the SW28 with the difference here being the peak torque output being in the 28-30Nm range compared to the 20Nm of the smaller SW20. For those in the know the SW28 uses the large MiGE motor and the SW20 uses the small MiGe motor, for reference the CSW V2 is around 7Nm.

The order process was smooth and straight forward, Sim-pli.city build to order so have a 3-4 week lead time vs SimRacingBay which seem to ship within a few days. I was happy to wait a few weeks for it to arrive as we had the 24Hrs of Spa approaching and I didn’t want it to arrive around that time and tempting me to install it so close to an endurance race where consistency and feeling comfortable with your setup are key.

Re-enforcing the Chassis

Whilst waiting for the Custom adapter and SW28 to arrive I decided that the chassis of the rig needed a few minor changes to improve its rigidity for the increased torque and loads the new wheel would place on it. Previously the rig had been designed to be collapsible but this did mean there was some flex at the connection point where the two pieces of the rig attached. With the rig now being in a permanent location I decided to upgrade the two main pillars from 40x40 to 80x40.

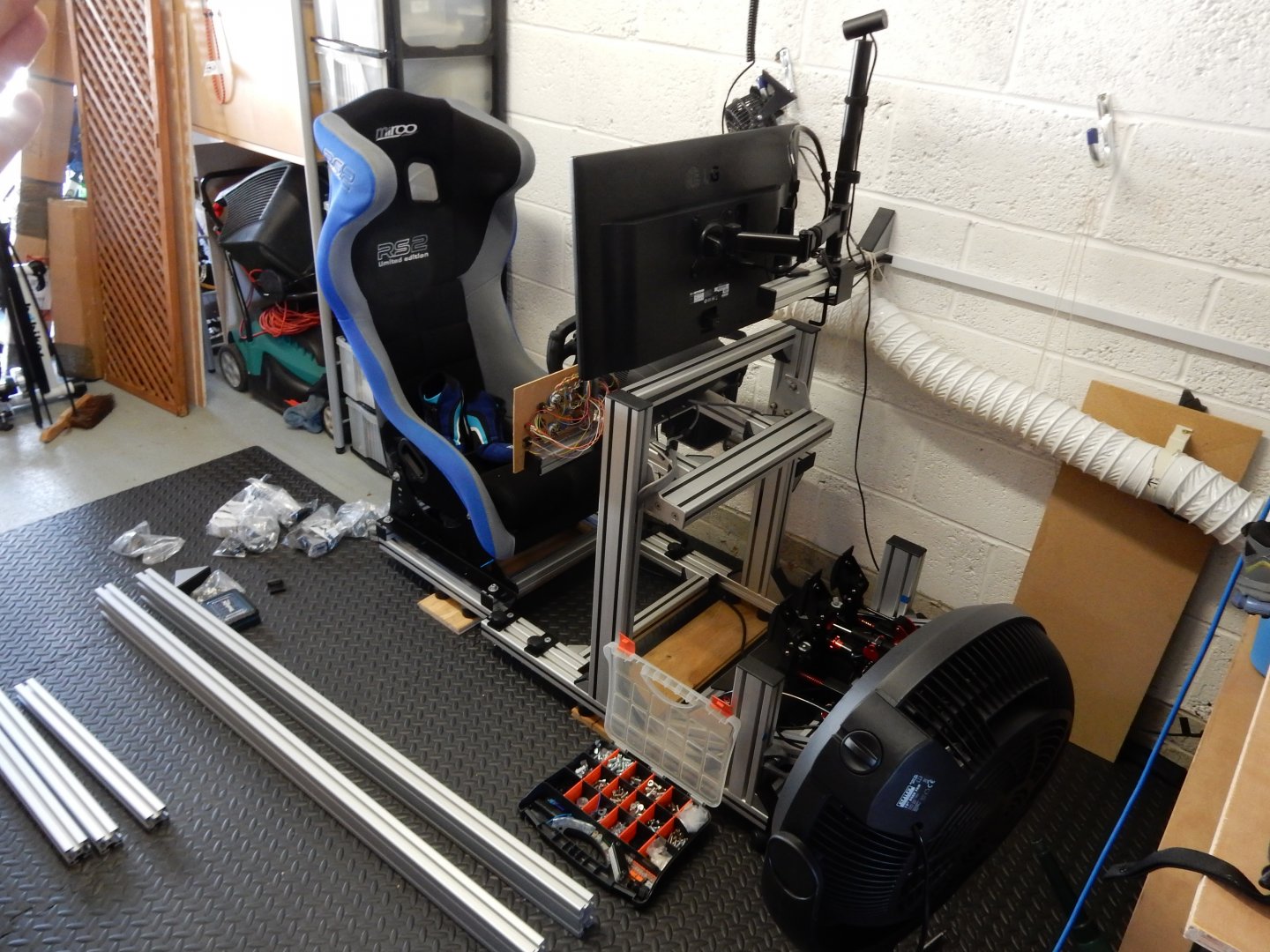

Below is a picture before the upgrade was started.

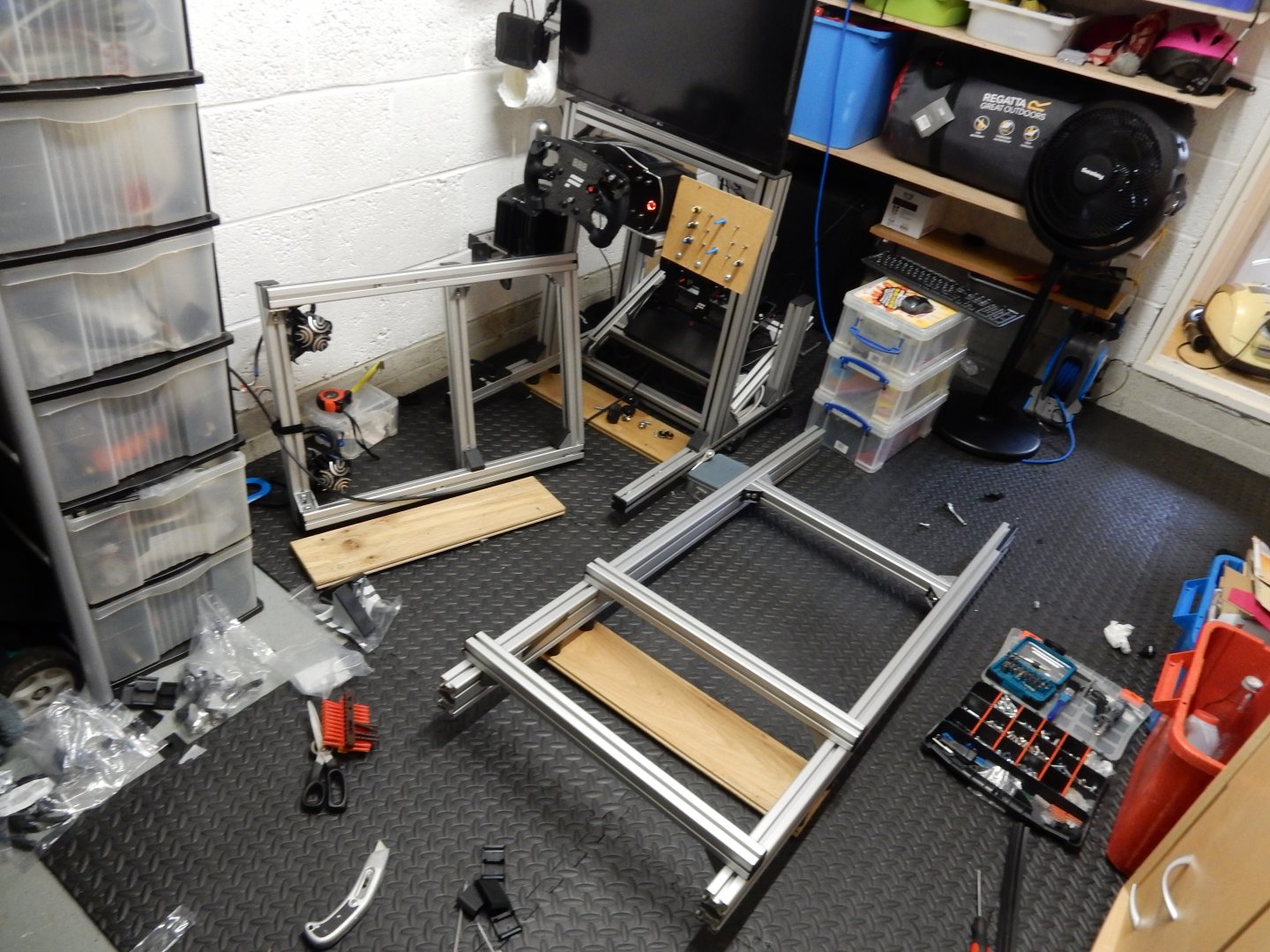

This is one of those moments where you think to yourself, why did I start this.

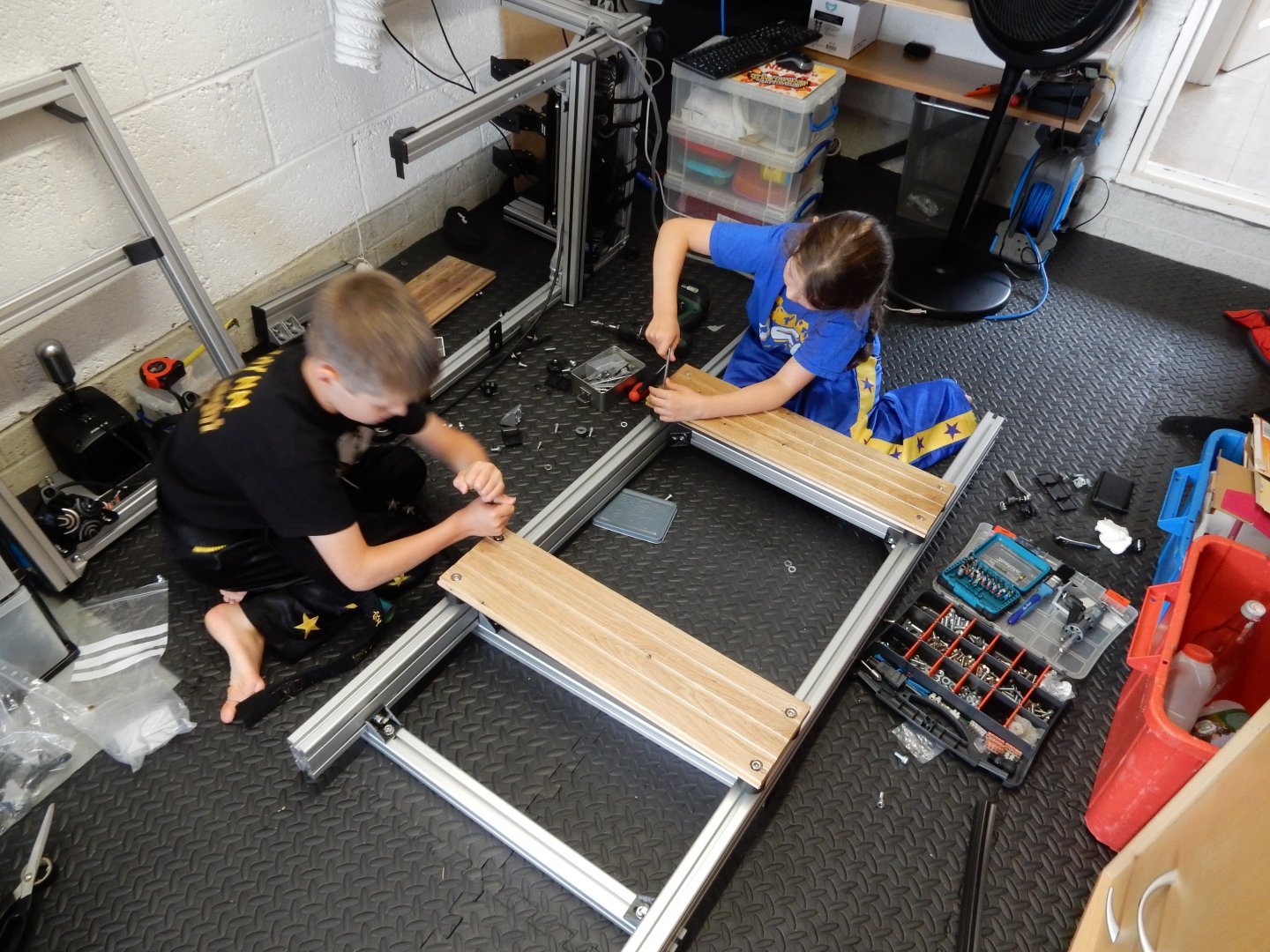

One of the great things with 80/20 is that the kids love to get involved helping put everything together, here you can see them attaching the vibration absorbing rubber mounts onto some oak planks to stop the floor deadening the vibrations from the transducers.

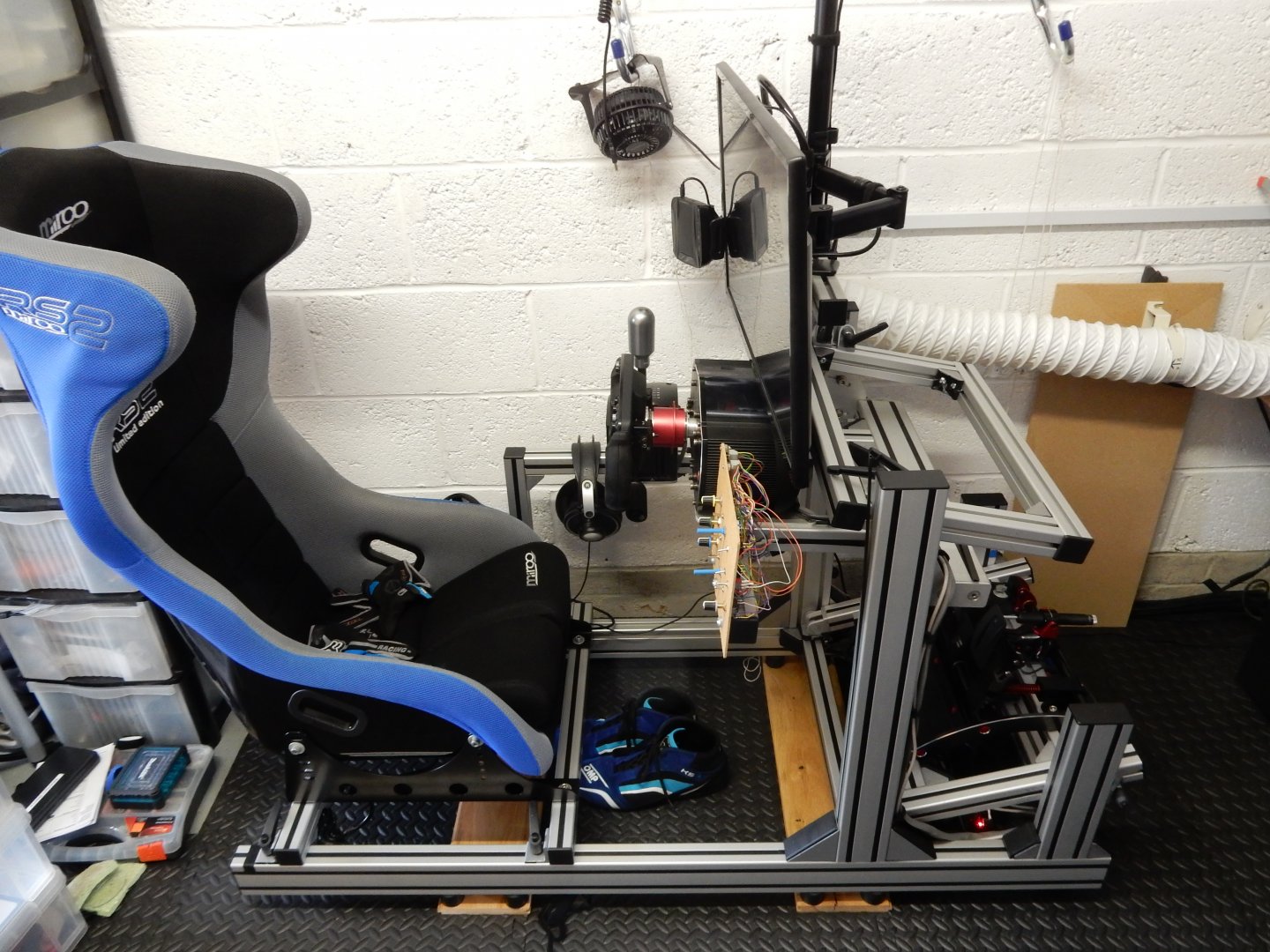

And a quick shot of the chassis in it's re-enforced state waiting for the SW28 to arrive.

Stage 1 of the build can be found here

Eviction to the Garage

After sitting pretty in the office of over a year, we had visitors from over the pond which required me to move the rig into the garage as a temporary measure. During the process and lots of hard lifting (these things get very heavy and cumbersome to move) I quickly came the conclusion that I didn't want to be moving the rig again anytime soon. At this point I decided to try and make a permanent home for it in the garage.

First port of call was to get something comfortable onto the hard floor so I opted for some Foam Garage Mats to cover the floor, these worked really well being easy to clean and also acting as a bit of an insulator from the concrete floor.

With the rig in the garage I now had no monitors or TV to use, I wanted to keep the desktop real estate of my two 24” 1920x1200 monitors from the office but didn’t really want to occupy that much space in the garage. So to keep the desktop real estate whist keeping the space usage down I opted for a single 4k 27” LG 27UD58 this was one of the cheaper IPS based panela. I went the IPS route as it would not really be used for gaming but more desktop based activities where IPS had better colour reproduction and viewing angles.

Exploring upgrade options.

As the rig was now in the garage the noise and vibration wouldn't carry into the rest of the house I now had a bit more flexibility on the types of upgrades I could look at in this constantly evolving project. My Fanatec CSW v2 had served me well for almost two years, with only the customary high pitch electronics whine that is common on the CSW v2 to fault it. Since being installed in the rig it has been subjected to five 24/12hr endurance races and easily over 10,000 laps during the last year and has been rock solid throughout.

I always wanted to RMA the CSW v2 for the electronics whine, but in the busy schedule of the endurance racing this year I just couldn't find the time to be without a wheel for more than a couple of days. I'd always said to myself that one day that I'd go to a direct drive system.

The jump to a DD wheel comes with many knock on expenses above and beyond the motor/controller systems themselves, alongside that you need to source a wheel, shifter and button electronics to go alongside it and these can also get almost as expensive as the base motor/controller themselves.

I know recently a lot of people have been converting their Fanatec wheels rims using conversion kits so that they can then mount these onto the DD kits and this was something I was had been looking at. My main concern here was this was a semi-permanent change to the wheel rim so once a wheel was converted it wouldn’t be easy to re-attach to the CSW v2 which I planned to keep for the children and having the portability between the two was high on my list of criteria for a replacement drive system.

Whilst I was investigating the options for mounting the Fanatec rims to a DD wheel, I came across a UK sim-racing site that does lots of modifications for Sim-racing gear. In a chance conversation about which quick release system they would recommend for attaching to a Fanatec wheel they offered to manufacture a custom made adapter for a DD wheel. This adapter would allow me to keep the Fanatec Wheel RIM’s in their original configuration and replicate the mounting mechanism of the CSW v2 onto a DD system including preserving the operation of the shifters and buttons.

And below is the custom adapter that got the ball rolling

At this point all the blockers that were holding me back had been resolved via the custom conversation adapter, this would allow the purchase of the DD system without the big expense of purchasing a new wheel for the DD kit.

Choosing a Direct Drive System

I had been looking at the DD market evolve over the last year there were a couple of turnkey products available. At the high end you have the Leo-Bodnar SimSteering series of wheels and at a cheaper price point the SimXperience Accuforce based series.

Additionally there is another option that is popular in a lot of the Sim-Racing forums and that is referred to as the OSW (Open Sim Wheel) eco system. This is basically an open source project where different motor controllers, associated electronics and motors can be combined in a DIY based project. Historically this has meant a lot of DIY to bring such a project into life and can be quite complex to the non-electronic engineer. In the last year this has become much simpler with the release of the SimuCube controller board. This board integrates a lot of the elements of the previous systems into one controller board designed specifically for simulation based environments such as Sim-Racing and all that is then required is to add a supported motor and a PSU.

With this change we also saw a lot of Sim-Racing companies starting to sell either a kit form of such systems or a fully assembled version. Whilst still a bit of a DIY project most of the complexity in these kits has been removed and this makes it accessible to a wider market.

Two of the more regarded EU companies that sell such kits are SimRacingBay and Sim-plicity, knowing that the kits are pretty much made from the same core components and both companies are generally held in good regard I opted for the UK based supplier as this came out about 20% cheaper for me.

I opted for the larger more powerful of the two systems on offer, the SW28 with the difference here being the peak torque output being in the 28-30Nm range compared to the 20Nm of the smaller SW20. For those in the know the SW28 uses the large MiGE motor and the SW20 uses the small MiGe motor, for reference the CSW V2 is around 7Nm.

The order process was smooth and straight forward, Sim-pli.city build to order so have a 3-4 week lead time vs SimRacingBay which seem to ship within a few days. I was happy to wait a few weeks for it to arrive as we had the 24Hrs of Spa approaching and I didn’t want it to arrive around that time and tempting me to install it so close to an endurance race where consistency and feeling comfortable with your setup are key.

Re-enforcing the Chassis

Whilst waiting for the Custom adapter and SW28 to arrive I decided that the chassis of the rig needed a few minor changes to improve its rigidity for the increased torque and loads the new wheel would place on it. Previously the rig had been designed to be collapsible but this did mean there was some flex at the connection point where the two pieces of the rig attached. With the rig now being in a permanent location I decided to upgrade the two main pillars from 40x40 to 80x40.

Below is a picture before the upgrade was started.

This is one of those moments where you think to yourself, why did I start this.

One of the great things with 80/20 is that the kids love to get involved helping put everything together, here you can see them attaching the vibration absorbing rubber mounts onto some oak planks to stop the floor deadening the vibrations from the transducers.

And a quick shot of the chassis in it's re-enforced state waiting for the SW28 to arrive.

Last edited: